Suav lag luam wholesale Tsis Siv Neeg Taum Taum Canning Kab Taum Canning Ntau Lawm Kab Machinery

Peb muab lub zog zoo hauv kev ua tau zoo thiab kev txhim kho, kev muag khoom, cov txiaj ntsig thiab kev lag luam thiab kev tshaj tawm thiab kev lag luam rau Suav lag luam wholesale Tsis Siv Neeg Taum Taum Canning Kab Taum Canning Kab Ntau Lawm Machinery, Peb ua siab dawb txais tos cov neeg siv khoom los ntawm ob qho tib si hauv tsev thiab txawv teb chaws tuaj rau kev sib tham nrog tuam txhab. peb.

Peb muab lub zog zoo heev hauv kev ua tau zoo thiab kev txhim kho, kev muag khoom, cov txiaj ntsig thiab kev lag luam thiab kev tshaj tawm thiab kev ua haujlwm rauTuam Tshoj Canned Food Machinery thiab Canning Machinery , Peb tab tom yuav pib theem thib ob ntawm peb txoj kev txhim kho. Peb lub tuam txhab suav nrog "tus nqi tsim nyog, sijhawm ntau lawm thiab kev pab cuam tom qab muag zoo" raws li peb txoj cai. Yog tias koj txaus siab rau ib qho ntawm peb cov khoom lossis xav tham txog kev txiav txim siab, nco ntsoov tiv tauj peb. Peb tab tom nrhiav rau pem hauv ntej los tsim kev lag luam kev sib raug zoo nrog cov neeg siv khoom tshiab thoob ntiaj teb nyob rau yav tom ntej.

Cov kaus poom Sweet pob kws ntau lawm kab piav qhia

Willman Machinery- cov kaus poom zaub mov thiab dej haus machinery chaw tsim tshuaj paus los ntawm Tuam Tshoj.

Peb lub Hoobkas tshwj xeeb hauv cov kaus poom zaub mov machinery ntau lawm, muab tag nrho cov kab ntau lawm rau cov neeg siv khoom. Raws li peb cov kev paub nplua nuj nyob rau hauv kev lag luam khoom noj khoom haus, peb tau muab peb cov neeg muas zaub tag nrho cov kab ntau lawm xws li cov kaus poom qab zib pob kws ntau lawm kab, cov kaus poom pineapple hauv syrup ntau lawm kab, cov kaus poom taum ntau lawm, cov kaus poom peas ntau lawm kab, kaus poom nceb ntau lawm kab ect, thiab peb tau txais lub koob npe zoo.

Los ntawm kev txheeb xyuas koj qhov chaw nyob hauv lub Hoobkas nrog rau koj qhov kev siv tiag tiag, peb cia siab tias yuav muaj teeb meem thiab daws lawv ib qho los ntawm ib qho, peb yog lub hom phiaj los muab koj qhov zoo tshaj plaws tsim kab tsim.

Cov kaus poom qab zib pob kws ntau lawm kab absorbs advanced technology thiab ua ke nrog qhov tseeb qhov teeb meem ntawm domestic thiab tsim technology txawv teb chaws, nws tau los ua ib tug tseem ceeb thiab nplua nuj tej khoom kab ntawm peb cov khoom.

4 mus rau 5 tons / teev, 6 mus rau 8 tons / teev, 8 mus rau 10 tons / teev muaj peev xwm yog cov kab ntau lawm.

Tsim tag nrho cov kab ntau lawm layout raws li koj lub Hoobkas siv tiag tiag.

Kev cog lus los muab kev tsim tsim nyog, txuag hluav taws xob thiab lub tshuab ruaj khov kom muaj peev xwm ruaj khov rau cov neeg siv khoom.

Cov txheej txheem tseem ceeb ntawm cov kaus poom qab zib pob kws

1. Cov khoom siv pob kws qab zib: Cov khoom siv pob kws qab zib yuav tsum tau ua kom siav thiab sib tw, nrog rau cov nplej daj rau lub teeb daj, cov tawv nqaij nyias, cov ntsiab lus qab zib siab, thiab cov xim zoo nkauj thiab tsw qab.

Cov ntaub ntawv raw yog ua tiav sai tom qab nkag mus rau hauv lub hoobkas. Cov khoom nyoos uas tau sau rau tib hnub yuav tsum tau ua tiav rau tib hnub.

2. Tshem tawm cov pob kws thiab pob ntseg: tshem cov tev thiab pob ntseg, ntxuav lawv hauv dej, thiab siv cov txhuam hniav tshem tawm cov pob ntseg thiab cov pob ntseg, thiab tshem tawm cov pob kws tsis tsim nyog xws li qub thiab npauj noj.

3. Sweet Threshing: Ua tib zoo saib xyuas cov nplej kom huv thiab huv si, tiv thaiv cov tub ntxhais los ntawm kev txiav tawm, xaiv cov nplej, tshem tawm cov whiskers, cores thiab lwm yam impurities, thiab cua sov tam sim ntawd.

4. Ua ntej ua noj thiab txias: 85-90 degrees Celsius dej

5. Qhov hnyav thiab cov kaus poom

6. Zaub mov npaj: teem 425g cov kaus poom qab zib pob kws ua piv txwv

| Qhov Loj | Nw (g) | Dw (g) | Fw (g) |

| 7113# | 425 | 270 | 270-275 : kuv |

100 kg dej; 1.2 kg ntawm refined ntsev; 7kg dawb granulated qab zib (hloov lub sijhawm raws li cov ntsiab lus qab zib ntawm ntau yam.)

7. Kev sib khi: Qhov kub ntawm qhov chaw ntawm lub tank yuav tsum tsis txhob qis dua 85 ℃ thaum lub sij hawm sealing.

8. Sterilization thiab txias

9. Cov lus qhia thiab ceev faj

A . Cov kaus poom khoob yog cov kaus poom tinplate nrog cov tshuaj tiv thaiv sulfur.

B . Cov xim, aroma, thiab saj ntawm cov pob kws qab zib tsis yog tsuas yog cuam tshuam nrog ntau yam ntawm cov khoom siv raw, tab sis kuj tseem cuam tshuam nrog kev loj hlob thiab kev loj hlob ntawm cov qoob loo. Nws yuav tsum tau ua tiav nyob rau hauv lub sij hawm tom qab sau nyob rau hauv lub mis-ripe lub sij hawm, thiab cov kev khiav yuav tsum ceev.

Yog tias tsim nyog, cov khoom siv raw tuaj yeem sau tau ob zaug hauv ib hnub.

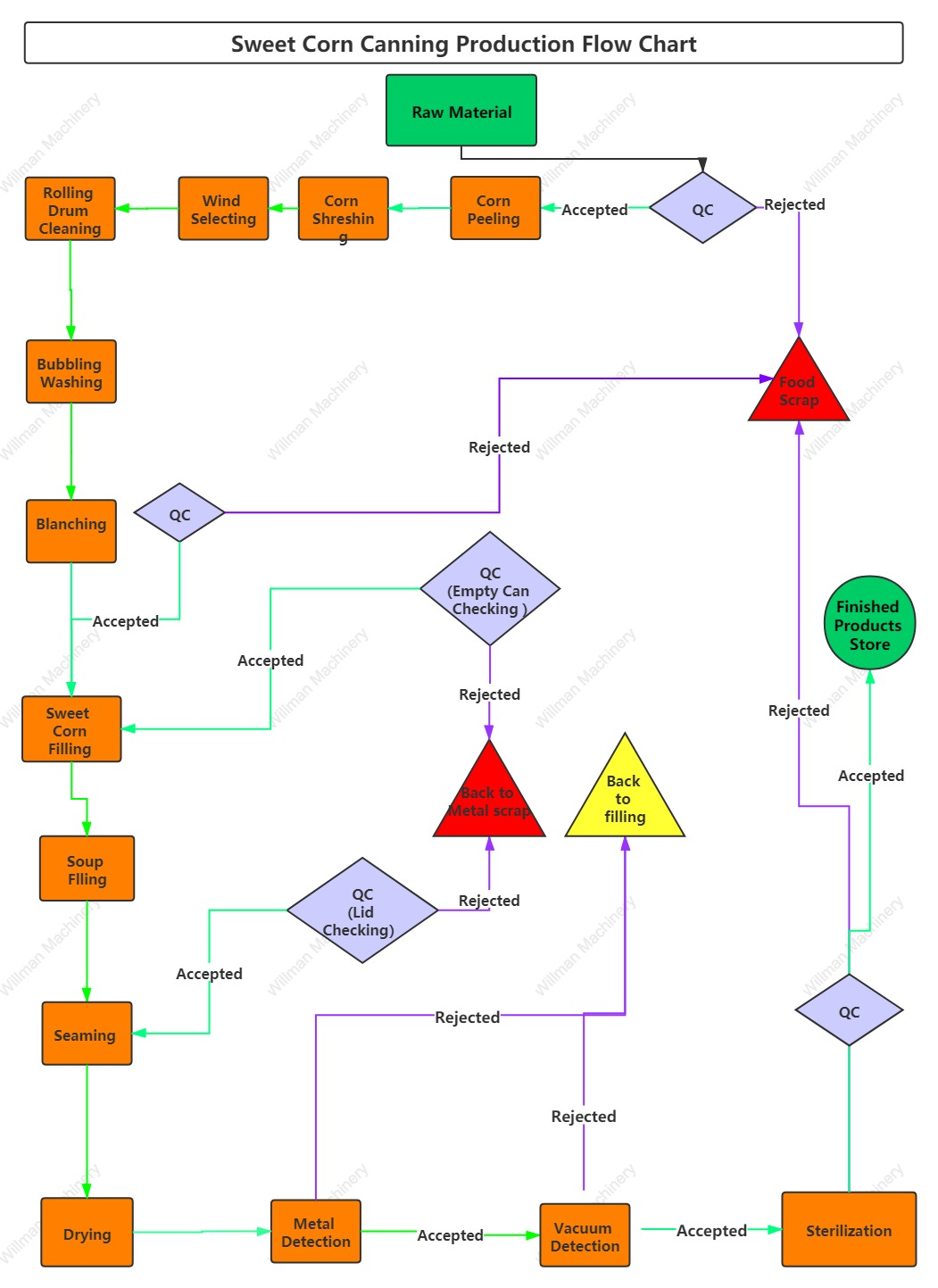

Cov kaus poom qab zib pob kws ntau lawm kab flow chart

Cov kaus poom pob kws qab zib no cov kab ntau lawm yog ua raws li ib lub tuam txhab loj uas cov khoom ntim cov pob kws qab zib nrog ceev ntawm 400 poom / min.

Txhua feem ntawm cov txheej txheem yog tswj tau zoo los ntawm raw khoom mus rau pob

Sweet Pob Kws Peeling Tshuab

Cov qauv ntawm Peeling Tshuab

Lub cev muaj zog yog ntsia rau ntawm lub hwj chim lub rooj zaum, lub ncej tsav yog ntsia rau ntawm lub rooj zaum bearing, lub ncej tsav yog txuas nrog lub cev muaj zog los ntawm txoj siv sia,

thiab tsav tsheb ncej yog muab kauv tuav thiab roj hmab ntsia hlau.

Cov ncej tsav tsheb yog sib npaug nrog cov ncej tsav tsheb los ntawm ib lub iav.

Lub log roj hmab yog lub tes tsho ntawm tus tsav ncej. Cov kabmob rooj zaum ntawm ob qho kawg ntawm tus tsav tsheb tsis nyob rau tib theem.

Sweet Corn Peeling Txoj Cai

Cov ncej tsav tsheb yog nruab nrog cov hlua khi thiab cov ntsia hlau roj hmab, thiab cov ncej sib kis tau nruab nrog ntau lub log roj hmab, cov ncej tsav tsheb thiab cov ncej sib txuas sib koom ua ke, thiab cov cuab yeej tev tuaj yeem sib npaug faib cov cob uas tau nkag mus rau hauv lub tshuab. txheeb ze rotating peelers. Thaum lub cob rotating nws tus kheej, nws mus rau pem hauv ntej smoothly. Thaum lub sijhawm txav mus los, cov tev tawm yog sib cais los ntawm cov tev tshwj xeeb, thiab cov tev tawm yog nias los ntawm lub rotating ncej nyob rau hauv ib qho instant kom tiav cov tev.

Peeling Ua tiav Rate

Cov pob kws tev tshuab feem ntau suav nrog lub cev tseem ceeb, lub cev yog nruab nrog cov khoom noj khoom haus, thiab lub rooj zaum fais fab txuas nrog lub cev.

Kev tshem tawm tag nrho yog 80% -95%,

Tus nqi crushing yog tsawg dua 1%,

Tus nqi poob qis dua 2%

Nws ua tiav cov pob kws tev tawm ua haujlwm zoo, es tsis txhob siv phau ntawv, thiab txhim kho kev ua haujlwm.

Sweet Corn Threshing Machine

Sweet pob kws threshing tshuab daim ntawv thov

Tus nqi qis: 98%

Peb tuaj yeem pom tias cov kaus poom pob kws qab zib, IQF cov pob kws qab zib, cov kaus poom qab zib pob kws tsuas yog ua los ntawm pob kws.

Pob kws threshing tshuab yog lub cuab yeej rau thresh kernel los ntawm pob kws cob. Qhov no yog qhov pib ntawm cov kaus poom los yog IQF los yog cov pob kws pob kws.

Qab Zib Pob Kws Rolling Drum Cleaning Tshuab

Rolling Drum Cleaning Tshuab

Qhov loj me yog customerized raws li lub peev xwm ib teev

Lub tshuab yog ua los ntawm SUS304 stainless hlau dov pannel nrog lub qhov ntawm nws.

Lub qhov loj yog 2 hli kom tshem tawm cov pob kws crushed.

Nrog kauv pannel nyob rau hauv kom txav lub pob kws rau pem hauv ntej.

Nws muaj ntau lub zog, tshem tawm cov whiskers, cores thiab lwm yam impurities thiab thaum kawg tau txais cov pob kws pob kws.

Blanching tshuab

Blanching tshuab yog rau pre-ua noj

Tshuab yog ua los ntawm SUS304 stainless hlau nrog conveying saw, nrog ntsuas kub.

Qhov loj me yog customerized raws li lub peev xwm ib teev

Ua ntej ua noj kub: 85-90 ℃, 3-5 feeb

Rau cov kaus poom pob kws qab zib ntau lawm, tsis tas yuav txias, vim tias thaum sib khi, peb yuav tsum xyuas kom meej tias qhov nruab nrab kub ntawm qhov filling tuaj yeem tsis tsawg dua 85 ℃

Sweet Corn kernel Filling Tshuab

Lub tshuab no siv lub khob ntsuas kom muaj nuj nqis rau qhov tseeb kom muaj nuj nqis, ua los ntawm SUS304 stainless hlau, Tsis siv neeg tswj kev pub mis, tsis muaj filling yam tsis muaj cov kaus poom.

Lub ntsiab lus tshwj xeeb ntawm cov pob kws qab zib kernel filling tshuab

| Yam khoom | Spec. | |

| Lub taub hau filling | 24 taub | |

| Muaj peev xwm | 100-400 poom ib min | |

| Siv tau txoj kab uas hla | D 52-153 hli | Cov kab sib txawv yuav tsum muaj qhov sib txawv |

| Siv tau qhov siab | H 39-178 hli | |

| Dimension | 1680 x 1900 x 2100 mm | |

| Hwj chim | 1.5 kwm | |

| Qhov hnyav | 1500 kgs |

Cov kaus poom qab zib pob kws kua filling thiab seaming tshuab

Lub tshuab no yog siab heev filling thiab seaming tshuab. Nws yog tsim los ntawm absorbing domestic thiab txawv teb chaws advanced technology.

Nws yog tsuas yog siv nyob rau hauv sau thiab seaming uas tsis yog-carbonated dej qab zib zoo li txiv hmab txiv ntoo kua txiv, los yog cov kaus poom zaub mov rau kua zaub filling thiab seaming.

Ntawm no peb siv nws rau sau kua zaub thiab seaming rau cov kaus poom qab zib pob kws

Lub sealing yog ob chav seaming spinning txoj kev, zaus hloov pauv ceev tswj, nrog cov yam ntxwv ntawm ruaj khov filling, kev kub ceev, raug ntim ntim, tsis muaj cov kaus poom tsis filling, tsis muaj dripping, tsis siv neeg tswj cov kua theem hauv lub tank.

Thiab lub tank filling tuaj yeem txuas nrog CIP (yog tias lub Hoobkas muaj) rau kev ntxuav thiab tshuaj tua kab mob. Qhov ntau lawm ceev yog tsis tu ncua adjustable.

| Filling thiab Seaming tshuab rau cov kaus poom qab zib pob kws canning kab | |||||

| Tsis muaj. | Yam khoom | WMGT-12-4 | WMGT-18-4 | WMGT-24-6 | WMGT-36-6 |

| 1 | Seaming taub hau | 4 | 4 | 6 | 6 |

| 2 | Filling Heads | 12 | 18 | nees nkaum plaub | 36 |

| 3 | Muaj peev xwm | 80-150 poom / min | 100-250 poom / min | 100 ~ 300 poom / min | 200 ~ 400 poom / min |

| 4 | Siv tau qhov siab | 39 ~ 170 hli | 39 ~ 170 hli | 39 ~ 170 hli | 39 ~ 170 hli |

| 5 | Siv tau Diameter | 52.3 ~ 99 hli | 52.3 ~ 99 hli | 52.3 ~ 99 hli | 52.3 ~ 99 hli |

| 6 | Compressed Cua | 0.6 MPa rau | 0.6 MPa rau | 0.6 MPa rau | 0.6 MPa rau |

| 7 | Hwj chim | 7,5 kwv | 7,5 kwv | 11 kwv | 11 kwv |

| 8 | Qhov Loj (mm) | 2800 x 1500 x 2200 | 3100 x 1800 x 2200 mm | 3500 x 1950 x 2200 mm | 4600 x 2300 x 2200 mm |

| 9 | Qhov hnyav | 3.5 t ua | 4 T | 5.5 t ua | 6.7t ib |

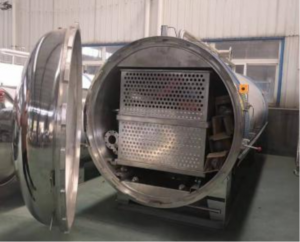

Retort lauj kaub rau Sterilization

Retort lauj kaub (Sterilization Mahcine)

1 Uniform water exchange mode realizes uniform temperature without dead angle .

2 Kub kub instant sterilization.

3 High sterilizing precision.

4 Kev txuag hluav taws xob.

5 Tag nrho cov chav kawm kom tsis muaj menyuam tuaj yeem tswj tau los ntawm lub computer PLC.

6 Lub sterilizing retort txais yuav simulative kub tswj system, thiab multilevel cua sov system tuaj yeem teeb tsa.

7 Kev ua haujlwm ntawm F ntsuas qhov ntsuas.

Technical Parameters

| Cov khoom npe | Specification |

| Sab hauv kab / raj ntev / ntim ntim (retort sterilizer) | 1200mm / 2000mm / txog 1.57 cbm |

| Txoj kev cua sov | Chav |

| Ua haujlwm siab tshaj plaws | 0.3Mpa (tsim siab: 0.35Mpa) |

| Ua haujlwm kub siab tshaj plaws | 143 ℃ (tsim kub: 147 ℃) |

| Tag nrho cov ntsia fais fab | Txog 15kw |

| Lub zog hluav taws xob | 380V / 50Hz (customizable) |

| Retort Khoom | Sib 304 |

| thickness ntawm retort lub cev | Sab hauv phab ntsa yog 10 hli tuab thiab lub tsho sab nrauv yog 5 hli |

| Pem teb qhov loj me | Txog 4855mm * 1630mm * 2157mm |

| Qhov hnyav (tsis muaj) | Txog 2500 kg |

Peb muab lub zog zoo hauv kev ua tau zoo thiab kev txhim kho, kev muag khoom, cov txiaj ntsig thiab kev lag luam thiab kev tshaj tawm thiab kev lag luam rau Suav lag luam wholesale Tsis Siv Neeg Taum Taum Canning Kab Taum Canning Kab Ntau Lawm Machinery, Peb ua siab dawb txais tos cov neeg siv khoom los ntawm ob qho tib si hauv tsev thiab txawv teb chaws tuaj rau kev sib tham nrog tuam txhab. peb.

Peb muab lub zog zoo hauv kev ua tau zoo thiab kev txhim kho, kev muag khoom, cov txiaj ntsig thiab kev lag luam thiab kev tshaj tawm thiab kev lag luam rau Suav lag luam wholesale Tsis Siv Neeg Taum Taum Canning Kab Taum Canning Kab Ntau Lawm Machinery, Peb ua siab dawb txais tos cov neeg siv khoom los ntawm ob qho tib si hauv tsev thiab txawv teb chaws tuaj rau kev sib tham nrog tuam txhab. peb.

Suav lag luam wholesaleTuam Tshoj Canned Food Machinery thiab Canning Machinery , Peb tab tom yuav pib theem thib ob ntawm peb txoj kev txhim kho. Peb lub tuam txhab suav nrog "tus nqi tsim nyog, sijhawm ntau lawm thiab kev pab cuam tom qab muag zoo" raws li peb txoj cai. Yog tias koj txaus siab rau ib qho ntawm peb cov khoom lossis xav tham txog kev txiav txim siab, nco ntsoov tiv tauj peb. Peb tab tom nrhiav rau pem hauv ntej los tsim kev lag luam kev sib raug zoo nrog cov neeg siv khoom tshiab thoob ntiaj teb nyob rau yav tom ntej.